The GAM 320A automatic PCB router machine is built for manufacturers who demand precision, speed, and reliability. It’s a compact, high-performance router that fits perfectly into modern SMT production lines.

If you’re working with small or mid-sized PCBs and need clean, accurate cuts, this machine delivers.

Precision Engineering That Performs

Precision Engineering That Performs

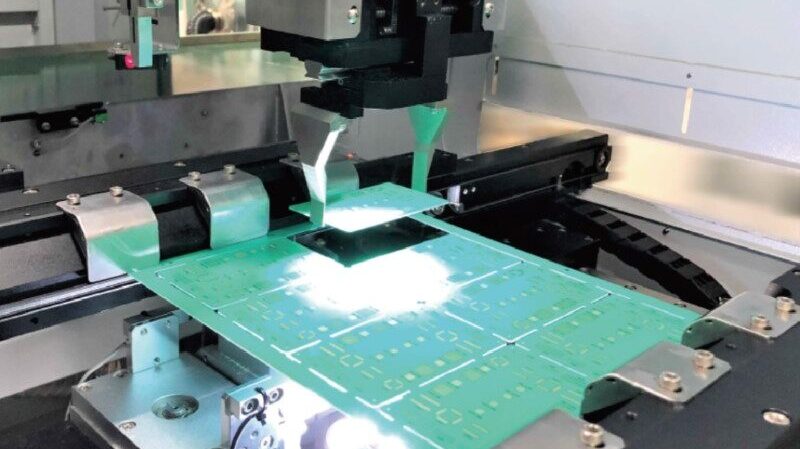

The GAM 320A is powered by a high-speed spindle motor.

Cutting precision reaches ±0.01 mm.

Repeatability is locked at ±0.005 mm.

This means clean edges, no burrs, and consistent quality.

Its rigid frame reduces vibration, keeping every cut stable and sharp—even at high speeds.

Dual Table for Continuous Production

Dual Table for Continuous Production

Dual working platforms allow for loading and unloading at the same time.

While one board is being cut, the next one is being placed.

This reduces downtime and increases efficiency.

It’s an ideal setup for manufacturers with growing production volumes.

Vision System with Smart Positioning

Vision System with Smart Positioning

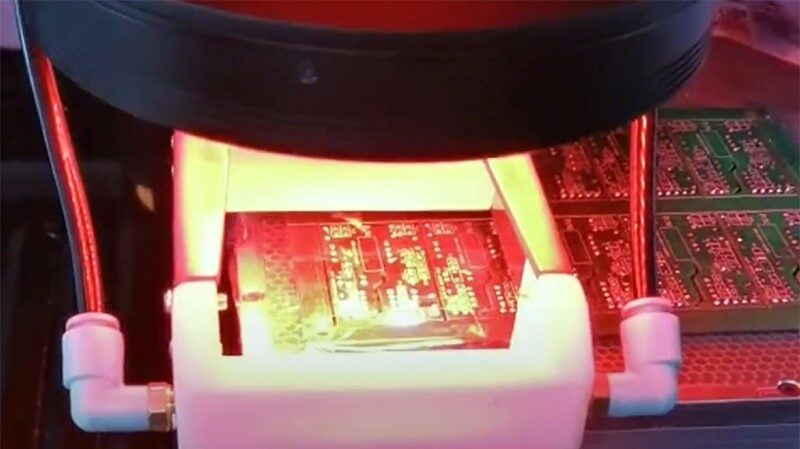

The machine uses a high-resolution camera for mark recognition.

PCBs are aligned automatically—no manual adjustment needed.

It saves time, reduces human error, and improves accuracy.

With just a few clicks, you’re ready to run the next batch.

Built for Flexible Production

Built for Flexible Production

The system supports PCB sizes up to 350mm x 300mm.

Multiple cutting depths and routing shapes are possible.

The fixture system adapts to different board sizes and layouts.

Perfect for both single-product lines and high-mix, low-volume manufacturing.

Dust-Free. Noise-Controlled. Operator-Friendly.

Dust-Free. Noise-Controlled. Operator-Friendly.

The GAM 320A comes with a dust collection interface.

That means a cleaner work environment and less post-processing.

The machine’s enclosed design also helps reduce noise.

It’s safe, quiet, and easy to use—ideal for long working hours.

Smart Features for Modern Manufacturing

Smart Features for Modern Manufacturing

- Barcode scanning and data tracking

- Optional auto tool change (ATC)

- Touchscreen control with an intuitive UI

- Built-in diagnostics and alerts

You get automation without complexity.

Why Choose Seprays Group?

Why Choose Seprays Group?

At Seprays Group, we design machines that keep production moving.

The GAM 320A automatic PCB router machine combines speed, accuracy, and intelligence—all in one compact system.

We offer:

We offer a full range of automated PCB depaneling technologies, including milling (engraving), laser, punching, and V-groove cutting, all on the same platform to meet any PCB production needs.

With service centers in 9 major cities and 31 countries and regions, you can get fast, localized, and professional support wherever you are.

With 32 years of manufacturing experience, we only choose to cooperate with the top three suppliers in the industry to ensure that each device has excellent performance and durability.

We proudly serve Fortune 500 and China Top 500 companies, helping customers improve efficiency, increase yield, and confidently meet the challenges of the ever-changing market.

Looking to take your PCB routing to the next level?

Please contact us—we’re here to help you scale smarter.

Spanish

Spanish Japanese

Japanese Korean

Korean Chinese

Chinese English

English